DOING Secures Custom 15Ton Batch Plastic Pyrolysis Equipment for Indian Client

Date:2026-01-28 16:50:29 News /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

In January 2026, DOING Company, a manufacturer of pyrolysis equipments and waste oil refining equipment, has signed a contract to supply a 15 Ton batch plastic pyrolysis equipment to a plastic recycling firm in India.

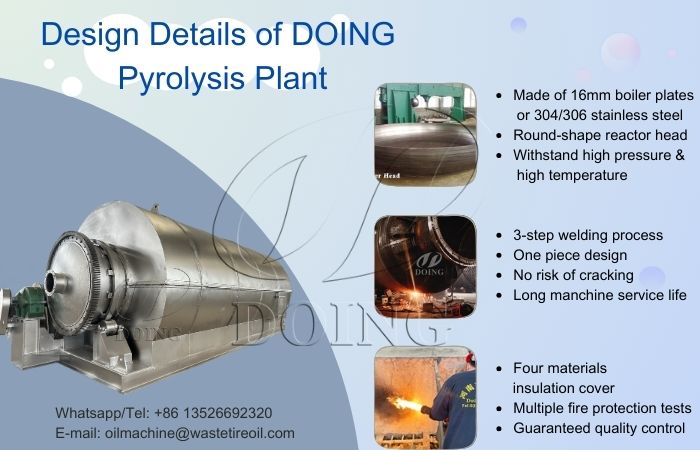

DOING batch plastic pyrolysis equipment

This Indian customer has been active in the plastic recycling field since 2012, possessing extensive experience in tire and plastic pyrolysis projects and having used pyrolysis equipment from several manufacturers. They previously purchased a used DOING pyrolysis equipment from a distributor and were satisfied with its performance. Now, the customer is preparing to build a dedicated plastic pyrolysis plant, and to ensure the reliability of the pyrolysis equipment to support their business expansion, they chose to purchase the equipment directly from DOING.

Details of DOING pyrolysis equipment

One of the key factors in this order was DOING's ability to provide customized configuration solutions based on the customer's needs. Last November, the DOING team met with the customer in India to gain a deep understanding of their project requirements, including space limitations at the new plant site and their emphasis on cost control. Subsequent communication further refined these details, allowing DOING to propose corresponding adjustments to the pyrolysis equipment configuration to meet the customer's budget without compromising essential functionality. The customer's confidence was further bolstered by DOING's excellent track record, including positive feedback on the durability of the previously installed used DOING pyrolysis equipment, and DOING's extensive experience in the Indian market.

DOING pyrolysis equipment projects in India

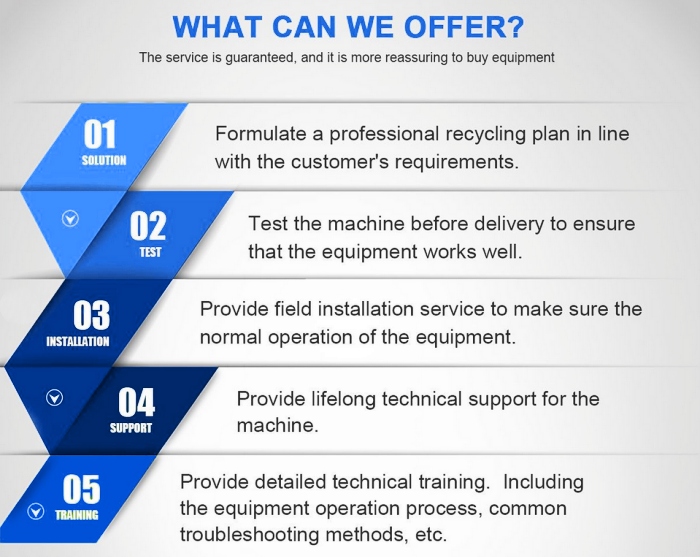

DOING's customizable pyrolysis equipment services include:

Material Handling and Pre-treatment: The feed pre-treatment module can be customized based on the plant's raw material composition, processing volume, and the type of pyrolysis equipment selected, balancing capital expenditure and operational stability.

Pyrolysis Equipment Capacity: DOING's pyrolysis equipment has a single unit capacity ranging from 100kg per day to 50 tons per day. If you require a larger capacity, we can also provide a solution with multiple units operating in parallel.

Exhaust Gas Treatment Depth: DOING pyrolysis equipment features multiple environmental protection facilities. Our customized solutions can increase or decrease these facilities accordingly, adjusting the depth of gas purification and scrubbing, allowing you to tailor emission control and maintenance costs to local regulations and operational costs.

Automation and Control: The level of automation of the pyrolysis equipment can be configured according to your specific needs, achieving a balance between intelligent monitoring and capital expenditure.

Core Pyrolysis Performance: The design prioritizes continuous pyrolysis efficiency and stable oil quality, and selects cost-optimized components to ensure the reliability of the pyrolysis equipment and control lifecycle costs.

DOING plastic pyrolysis equipment manufacturer

The final 15 Ton batch plastic pyrolysis system embodies the aforementioned balance, achieving reliable throughput and waste plastic-to-fuel oil conversion rates at a competitive price, while maintaining ease of operation and maintainability, thus meeting customers' emphasis on quality, price, and long-term value.

Production of the 15 Ton batch plastic pyrolysis equipment is underway at DOING Company's factory, with delivery scheduled for two months to support the client's new plastic recycling operations.