Tire recycling machine

Date:2013-06-20 09:03:57 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Tire recycling machine

Tire recycling machine

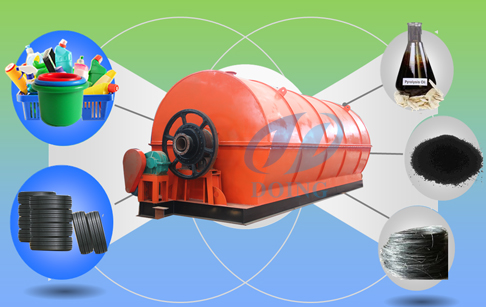

DOING tire recycling machine,with the superiority of low capital investment and high fuel financial price, has become the first preferred waste disposal method in many countries. This profitable project was established in many countries with low labor costs and less environmental restriction worldwide. DOING GROUP from Henan , China installed more than one thousand highly sophisticated and advanted waste tire recycling machine, which are widely appreciated by customers owing to the various advantages and profits.

Tire recycling machine

Tire recycling machine

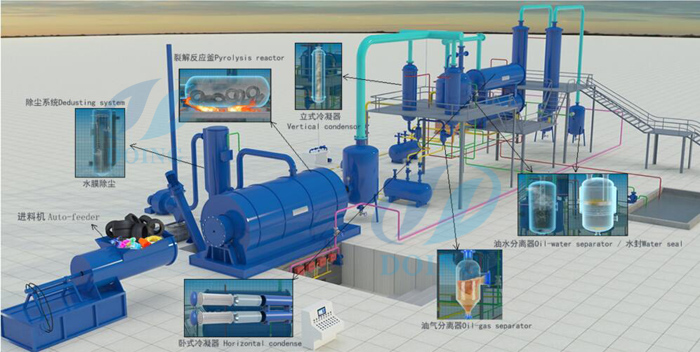

Waste tire recycling machine pyrolysis process:

Tire recycling machine process tire to fuel oil

Tire recycling machine process tire to fuel oil

a. Use auto-feeder to feed the waste tires into reactor automatically, seal the feeding inlet door tightly.

b. Heat the reactor by burning the following fuel material: coal, wood, natural gas, or fuel oil in the combustion system. The reactor will be heated slowly, when the temperature reaches around 250 degree Celsius, the oil gas will be formed.

c. After processed by doing waste tire recycling pyrolysis machine, the oil gas will go to the cooling system to be liquefied. The gas which can not be liquefied under normal pressure will be designed to go back to combustion system through safety device instead of the fuel material to burn the reactor, which isenvironmental friendly and can save you much energy.

d. After finishing oil collecting, the temperature of reactor will be down, while, carbon black can be discharged automatically at the same time.

e. when the temperature falls down to 100 degree Celsius, workers can open the door of reactor to discharge the steel wire.

f. Start another batch working.

| Technical parameter of tire recycling machine | ||||

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tire | Waste tire | Waste tire |

| 3 | Structural form | Horizontalrotation | Horizontalrotation | Horizontalrotation |

| 4 | 24-hourCapacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operatingpressure | Normal | Normal | Normal |

| 7 | Material ofReactor | Q245R | Q245R | Q245R |

| 8 | Thickness ofReactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Coolingarea | 100sqm | 100sqm | 100sqm |

| 13 | Kind oftransmission | Internal geardrive | Internal geardrive | Internal geardrive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size ofReactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittentoperation | Intermittentoperation | Intermittentoperation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |