Waste tire recycling equipment

Date:2013-06-19 18:58:25 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Waste tire recycling equipment

Proper disposal of waste tire is essential because this kind of waste materials has seriously polluted our environment. Compared with landfill and burning, recycling waste tire into useful resources is a better and meaningful method.

Doing group has developed the latest waste tire recycling equipment to deal with the waste tire in an eco-friendly and profitable method. The tyre recycling machinery also can be used to dispose waste plastic, waste rubber, medical waste

.

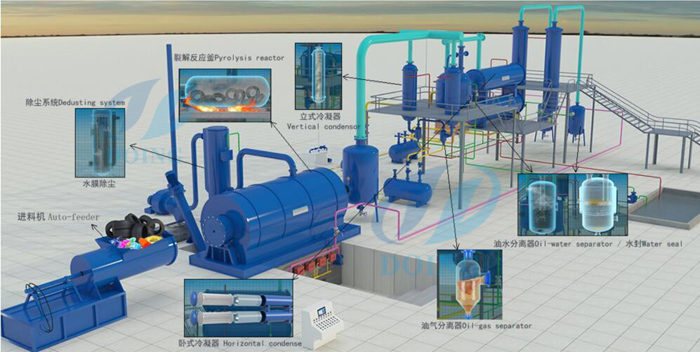

Waste tire recycling equipment

Waste tire recycling equipment could be able to Automatic feeding, automatic slag, automatic alarm, automatic decompression, automatic adjustment of negative pressure, exhaust automatic recovery. Only need two workers to control the whole system, can save your cost.

Waste tire recycling equipment working process:

Used tire recycling equipment working process

1) feed the raw material into furnace automatically or manually, then seal the feed inlet system.

2) heat the reactor by burning the fuel material(coal,or wood,or natural gas ,oil ) in the combustion system.

the reactor will slowly become heat ,when the temperature reach around 250 degree Celsius, the oil gas will be formed.

3) After processed by our technology, the oil gas will go to cooling system for cold liquid oil.the gas which can not become liquid under normal pressure , will be designed to go back to combustion system through safety device instead of the fuel material to burn the reactor, which is environmental friendly and can save you much energy.

4)After finished oil produce ,the temperature of reactor will be down,while,carbon black can be discharged automatically.

5) when the temperature fall down to 100 degree Celsius,worker could opened the door of reactor to discharge of steel wire.

6) Then can start to another batch working.

Final product:

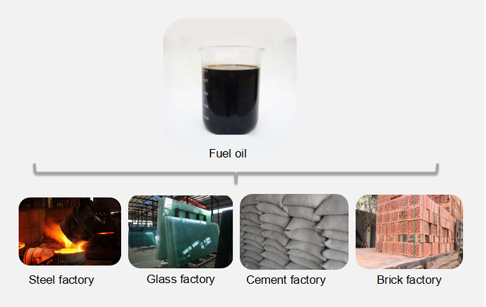

Fuel oil application

Fuel Oil: 45% to 52%. Can be used as industrial fuel for burning.

Carbon black application

Crude Carbon Black: 30% to 35%. Can be sold to the brick factory as internal combustion or to the factory needing it as raw materials, such as tire, shoe, cable and sealant companies.

Steel Wire: 10% to 15%. Can be sold to the iron and steel company directly

Gas: 5%. Can return to the hearth to burn as fuel, so that you can save cost to buy wood or coal.

Waste tire recycling equipment advantage

Safety:

1. Our reactor is made by automatic welding machine. It makes welding much more proportional and firm with welding wire and welding flux, which ensures machine’s safe running in the best temperature as high as 45°C for the highest oil yield.

2. X-Rays detection will make 100% testing reactor in case of pores during welding.

3. After professional heating treatment, the reactor’s p repress will be eliminated and become more solid and cast-in block.

4. Two steps safety devices prevent gas from going back which keeps machine running safely.

5. With vacuum system, equipment will be much safe operating in negative pressure.

| Place of Origin | Henan, China (Mainland) |

| Brand Name | DOING |

| Model Number | DY-1-8 |

| type | tire machine |

| tire machine type | Waste tire recylcing equipment |

| land require | 200 sqm |

| weight | 35 ton |

| length | 6600mm |

| colour | according to customer’s request |

| modal | 8 ton |

| diameter | 2200mm |

| one batch time | 16-20 hour |

| welder | aoto-welding |

| Price: | FOB USD 35000.00~70000.00 / Set |

| Minimum Order Quantity: | 1 Set |

| Port: | Qingdao/Tianjin |

| Packaging Details: | according to customer’s request |

| Delivery Time: | 20 days after deposit |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 10 Sets per Month |