Used tire pyrolysis machine

Date:2013-06-19 15:20:36 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Used tire pyrolysis machine

We are engaged in offering a wide range of used tire pyrolysis machine- DY-10tons. This waste tire pyrolysis machine can help us process waste tires to a good quality products such as fuel oil, carbon black and steel wire with a high quality.

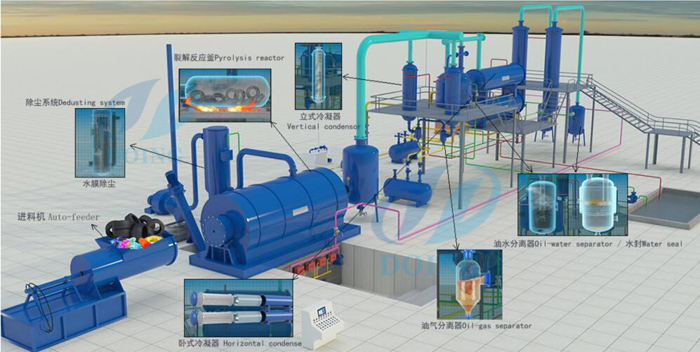

All our machine are equipped with host (with shell body machine) and gas, cooling system (tank cooling, coil type cooling, tubular cooling, etc, can choose), cooling tower and intermediate tanks that aid them in performing well.

The two keys of used tire pyrolysis machine are reactor and cooling system.

The reactor of used tire pyrolysis machine

Reactor directly decides the used recycling pyrolysis machine safety and service life. It is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

For cooling systems, there are two steps. Top cooling pipe is the first step. The second is condenser. We have three condensers. And there are 57 pipes in one condenser. Diameter is 48mm for one small pipe. The heat exchanging area is about 13square meters for one condenser. So the total cooling area is about 40 square meters, which will guarantee you a high oil yield.

Used tire pyrolysis machine process used tire to fuel oil ,carbon black and steel wire

Used tire pyrolysis macine pyrolsyis used tire to fuel oil ,carbon black and steel wire

1) Put the waste tyre/plastic into reactor and make reactor rotate clockwise 0.4-0.8 r/min. Seal the feeding inlet door tightly and make sure there is no gas leakage.

(2) Heat the reactor by using coal, charcoal, fuel gas, wood etc. as heating materials. The reactor will be slowly heated, and when the temperature reach about 250 degrees, the oil gas will be formed.

(3) The oil gas coming out from the reactor then goes to condensing system and become liquid oil. The gas which can’t be liquefied under normal pressure will be designed to go back to combustion system through safety device. It can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

(5) After finishing oil production, the temperature of pyrolysis reactor will fall down, when the temperature falls down to 40 degrees Celsius, we can get carbon black and steel wire.

Used tire pyrolysis machine final product and application

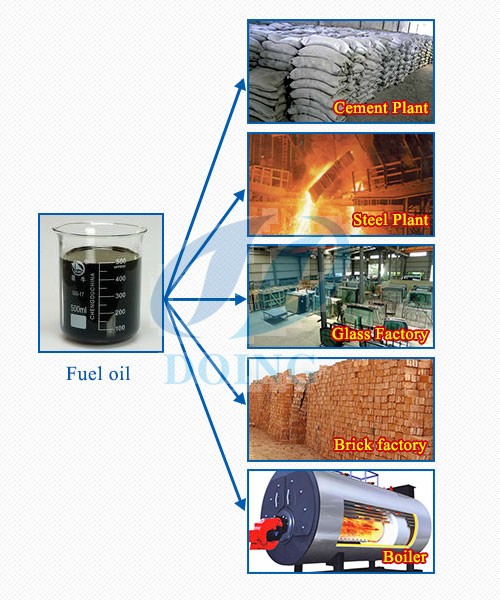

Fuel oil application

Fuel Oil (45% to 52%)

The main application of oil products produced by Doing Used tire pyrolysis machine is the fuel oil that is wide used for industrial and commercial purposes. 45% to 52% oil of the amount of recycled scrap tyres can be carried with licensed tanker trucks.

Steel Wire (10% to 15%)The third product of Doing tire pyrolysis pyrolysis machine is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire in local market.

Carbon Black (30% to 35%)

Carbon black application

The second product of Doing Used tire pyrolysis machine is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compared to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.

Oil gas (About 10%)

We get about 10% oil gas during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.