Cottonseed oil making machine

Date:2013-09-30 18:19:34 Cooking Oil Production Line /Give me the price / Leave a message- Tel: 0086-371-5677 1823

- Whatsapp/Cel: 0086 135 2662 7860

- Email: market@doinggroup.com

The function of cottonseed oil making machine is to get cooking oil from cottonseed. For the whole set of cottonseed oil making machine, there are three main sections: cottonseed pretreatment and oil pressing machine, cottonseed oil solvent extraction machine and cottonseed oil refinery machine.

The cottonseed pretreatment and oil pressing machine:

The cottonseed oil pretreatment machine is used to process cottonseed and make it more easy to extract cottonseed oil by pressing or solvent extraction method. The cottonseed oil pressing machine is used to get pressed cottonseed oil, and the residual oil rate in cakes is about 6-7%.

Cottonseed pretreatment and pressing machine

Cottonseed pretreatment and pressing machine

a. Cleaning machine: To remove the impurities from the cottonseed.

b. Dehuller machine: To remove the shell of cottonseed.

c. Vibrating separator: To separate the shell and cottonseed kernel.

d. Flaking roller: To make the cottonseed into flakiness.

e. Cooker: To adjust the water content of the cottonseed.

f. Oil presser or oil pre-presser: To get pressed crude cottonseed oil.

The cottonseed oil solvent extraction machine:

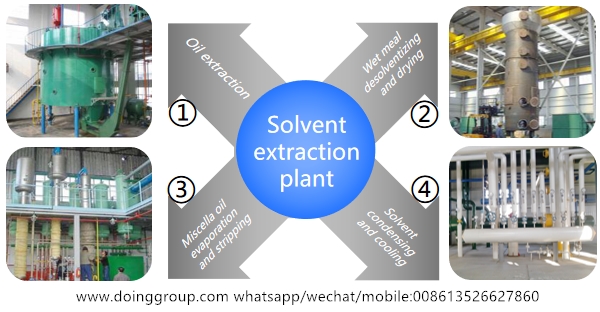

The advantage of cottonseed oil solvent extraction machine is to get more oil from the cottonseed cakes. After extracting the cottonseed oil by solvent, the residual oil in meal will be less than 1%. There are four main parts in the cottonseed oil solvent extraction process.

Cottonseed oil solvent extraction machine

Cottonseed oil solvent extraction machine

a. Mixing oil with solvent: After going into the solvent extractor, spaying the solvent on the cakes to get miscella and wet meal (with solvent).

b. Separating the solvent from wet meal: It is called desolventization. After drying, the dry meal can be used as animal feed.

c. Separated crude cottonseed oil from the miscella: Through steaming and stripping, the crude cottonseed oil will be sent to the next workshop.

d. Recycling the solvent: Solvent will be condensed and recycled to the tanks.

The cottonseed oil refinery machine:

After getting crude cottonseed oil from pressing section and solvent extraction section, the crude oil enters oil refinery section. There are four main parts in cottonseed oil refinery process.

Cottonseed oil refinery machine

Cottonseed oil refinery machine

a. Degumming part: It is to remove gums in crude cottonseed.

b. Deacidification part: It is used to remove the free fatty acid in the crude cottonseed oil.

c. Decolorization part: The white clay is used to remove the pigments of the cottonseed oil.

d. Deodorization part: The bad smell of the cottonseed oil is removed by steam.

Henan Doing Company can design the cottonseed oil making machine for you according to your need. You can choose to use pressing method or solvent extraction method to make cottonseed oil. The cottonseed oil refinery machine has three types for you to choose. Welcome to leave your needs!