Technical Comparisons Between Semi-continuous and Fully-continuous Pyrolysis Machines

Date:2025-12-05 16:13:27 Industry Trends /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

In recent years, the design of pyrolysis equipment has been continuously innovated. Continuous pyrolysis machine has significant advantages in efficiency and environmental protection compared with traditional batch pyrolysis machine. DOING has designed two types of continuous pyrolysis machines: semi-continuous and fully continuous. These two kinds of pyrolysis machines have great differences, watching the following 7 aspects introduction to choose the appropriate equipment according to your actual needs.

DOING continuous pyrolysis machine differences introduction

DOING continuous pyrolysis machine differences introduction

1.Operational Mode & Throughput:

Semi-Continuous Pyrolysis Machines

Operational Mode: Semi-continuous pyrolysis machine runs in cycles—one batch of waste is fed, processed (pyrolysis), and discharged before the next batch starts, achieving an operating efficiency of three furnaces every two days.

Processing Capacity: 5-20 tons per day, suitable for small businesses with limited waste supply.

Fully-continuous Pyrolysis Machines

Operational Mode: 24/7 non-stop operation via automated feeding and discharging systems. Waste is continuously fed into the reactor, and products can be discharged without stopping, allowing for continuous operation for 45 days.

Processing Capacity: Daily capacity ranges from 15–50 tons, designed for large-scale or industrial scale waste recycling treatment factories.

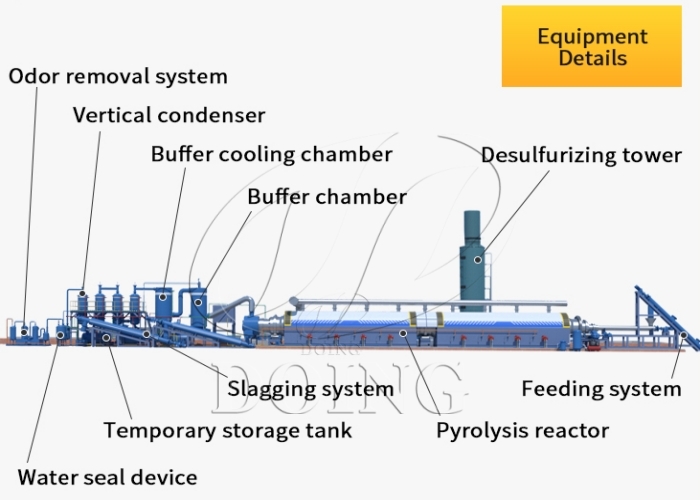

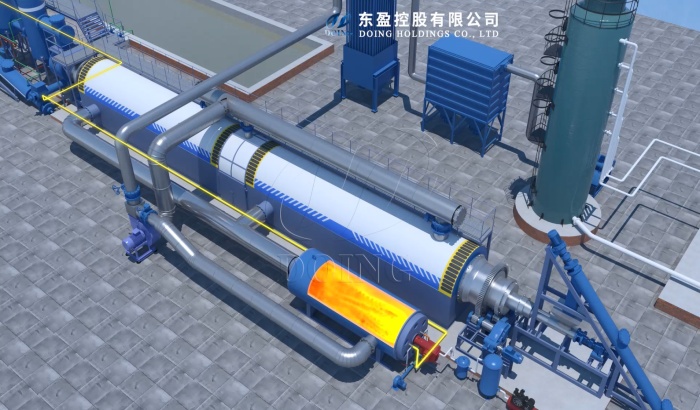

DOING continuous pyrolysis machine details

DOING continuous pyrolysis machine details

2.Raw Material Types & Feeding Method

Semi-Continuous Pyrolysis Machines

Raw Material Specifications: Crushed to 2cm of tire rubber powder, plastic, and oil sludge can be treated.

Feeding Method: Continuous feeding by screw conveyor.

Fully-continuous Pyrolysis Machines

Raw Material Specifications: Requires higher quality material; tire rubber needs crushing to 2mm, and soft plastics to 15mm.

Feeding Method: Automated feeding via screw-sealed auger, adjustable via PLC.

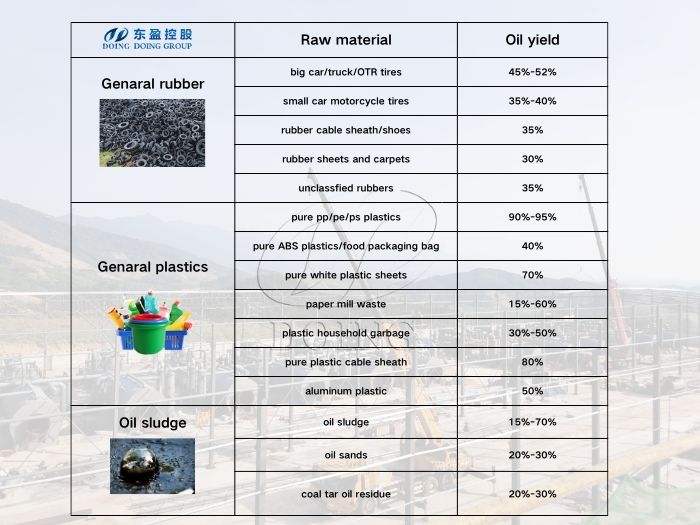

Waste pyrolysis oil yield

Waste pyrolysis oil yield

3.Carbon black discharging

Semi-Continuous Pyrolysis Machines

Side discharge is used, and the carbon black is discharged after the reactor cools down. It is then lifted and packaged by a carbon black elevator.

Rear discharge is used, eliminating the need for reactor cooling. The carbon black is directly discharged at high temperature to the cooling tank, resulting in high efficiency.

Fully-continuous Pyrolysis Machines

Continuous discharge with cooling via a jacketed spiral conveyor, ensuring no reactor shutdown.

DOING carbon black discharge system

DOING carbon black discharge system

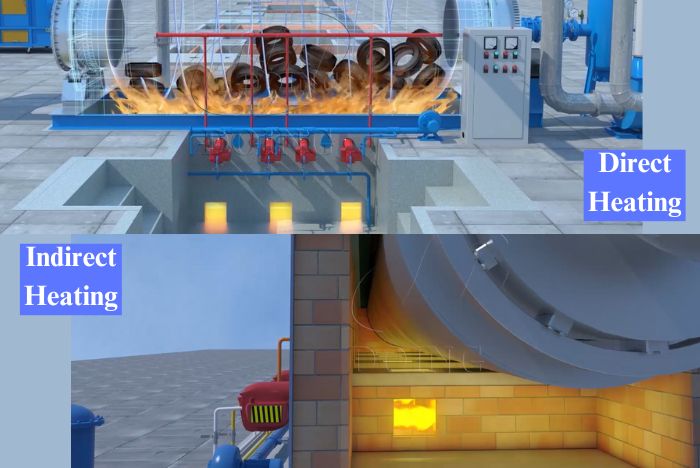

4.Heating method

Semi-Continuous Pyrolysis Machines

Direct heating using coal, natural gas, or recycled combustible gas.

Fully-continuous Pyrolysis Machines

Indirect heating for better reactor lifespan, using the same fuel types.

DOING continuous pyrolysis machine heating method

DOING continuous pyrolysis machine heating method

5.Production efficiency

Semi-Continuous Pyrolysis Machines

Energy Efficiency: Requires reheating the reactor between batches, leading to moderate energy loss. However, DOING models integrate heat insulation layers (high-temperature resistant ceramic fiber) to reduce heat dissipation by 20–25%.

Resource Recovery: 40–45% fuel oil, 30–35% carbon black, 10–15% combustible gas.

Fully-continuous Pyrolysis Machines

Energy Efficiency: No repeated heating/cooling cycles, resulting in 30–40% lower energy consumption than semi-continuous models. DOING continuous pyrolysis machines recycle 100% of combustible gas to heat the reactor, achieving near-self-sufficiency in energy.

Resource Recovery: Higher yields due to stable reaction conditions: 45–50% fuel oil, 35–40% carbon black, 15–20% gas.

DOING continuous pyrolysis machine exhaust gas recovery system

DOING continuous pyrolysis machine exhaust gas recovery system

6.Environmental Features

Semi-Continuous Pyrolysis Machines

Sealed discharging, reduced carbon footprint compared to batch systems.

Fully-continuous Pyrolysis Machines

Fully sealed feeding and slag discharge, the most eco-friendly option for pyrolysis machine operation.

Environmentally friendly carbon black air transport system

Environmentally friendly carbon black air transport system

7.Labor Requirements & Operational Complexity

Semi-Continuous Pyrolysis Machines

Labor Needs: Requires 2–3 operators per shift to handle feeding, monitoring, and discharging.

Operational Complexity: Simple manual adjustments for feeding and discharging, ideal for small-scale operations.

Fully-continuous Pyrolysis Machines

Labor Needs: Only 1–2 operators per shift for automated processes.

Operational Complexity: High automation via PLC touchscreen for synchronized operations, suitable for large-scale operations.

DOING continuous pyrolysis machine PLC system

DOING continuous pyrolysis machine PLC system

The choice between semi-continuous and continuous pyrolysis machines depends on the scale of your operation and your specific recycling needs. Semi-continuous systems offer flexibility and cost-effectiveness for smaller operations, while fully continuous pyrolysis systems are better suited for large-scale recycling, offering higher capacity and greater efficiency.

DOING provides customized pyrolysis solutions with built-in environmental compliance (exhaust gas treatment, zero wastewater), meeting global standards for sustainability. For more information and tailored solutions, contact DOING right now.