What is the common points and differences between batch and continuous waste tire pyrolysis plant?

Date:2018-06-06 17:55:57 Pyrolysis machine FAQ /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

The batch and continuous waste tire pyrolysis plant all adopt the principle of pyorlysis technology to treat waste tires. They have some common points and differences. Customers can choose according to their actual needs.

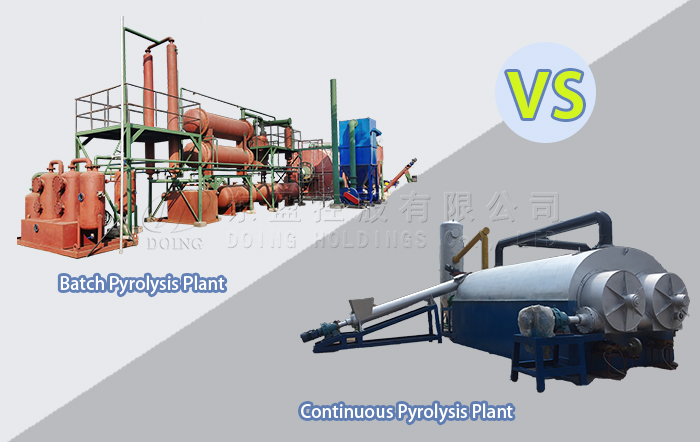

Batch tire pyrolysis plant VS continuous waste tire pyrolysis plant

Batch tire pyrolysis plant VS continuous waste tire pyrolysis plant

Batch and continuous waste tire pyrolysis plant have many common points.

1. Advanced condensing system for high oil output

Both batch and continuous waste tire pyrolysis plant adopt the most advanced condensing system, through seven-step condensation, the oil gas is fully cooled, so that they all have a high oil yield.

2. Long service life

Both the batch tire pyrolysis reactor and continuous reactor adopt high quality boiler plate material and are made strictly according to high pressure vessel standard. They are resistant to high temperature and pressure and have a long service life.

3. Energy saving

The extra gas produced in the pyrolysis process that cannot be liquefied to oil under normal pressure would be recycled to heat the pyrolysis reactor as fuel. The gas generated in the pyrolysis process has more caloric value, which will save a lot of energy for the whole working process. Batch and continuous waste tire pyrolysis plant are all designed this function.

4. Environmental friendly

It is absolutely environmental friendly in the production process of batch and continuous waste tire pyrolysis plant. The discharge of solids, liquids and gases can meet the standard requirements. The equipment has normal machine operation sound in the normal operation and doesn’t have any other noise.

5. Safety

Batch or continuous waste tire pyrolysis plant is equipped with mature safety devices, such as thermometer, pressure gauge, safety valve, electric control system. Water seal and vacuum system will prevent exhaust gas from going back to condensers and reactor. Thus, unnecessary accident can be avoided. The equipment can be operated safely.

Main common points between batch and continuous waste tire pyrolysis plant

Main common points between batch and continuous waste tire pyrolysis plant

Above are the main common points that batch and continuous waste tire pyrolysis plant have. Then what are the differences between them?

Characteristics of batch waste tire pyrolysis plant

The batch waste tire pyrolysis plant has low automation and mainly operated by labour. This batch type waste tire pyrolysis plant needs to be stopped after every process for discharging residues (carbon black and steel wire) and feeding waste tires again. For one complete process, it takes about 16-20 hours, almost one whole day. For a new starting business, batch type waste tire pyrolysis plant is enough for the personal business.

Batch waste tire pyrolysis plant

Batch waste tire pyrolysis plant

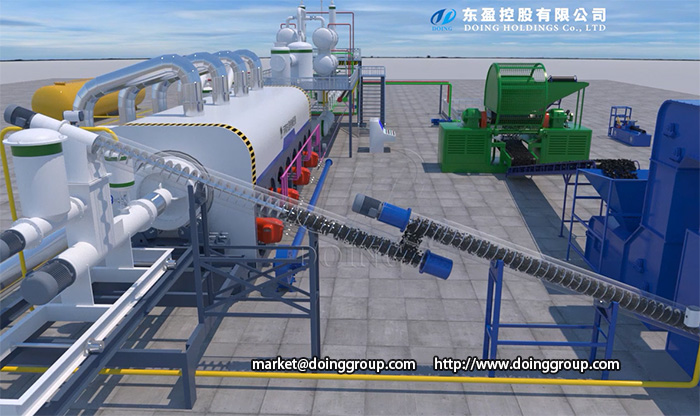

Compared with the batch pyrolysis plant, the continuous waste tire pyrolysis plant has the following advantages and characteristics. It is suitable for large scale waste tire dealing companies or government projects.

Advantages and characteristics of continuous waste tire pyrolysis plant

1. With accurate calculation system

The continuous waste tire pyrolysis plant is equipped with an accurate calculation system to ensure that the waste tires are fully pyrolyzed in the reactor, and fully converted into oil gas, thus the oil yield is high.

2. Unique slagging system

The continuous waste tire pyrolysis plant adopts unique slag discharge design, which can realize the automatic separation of carbon black and steel wire. Customers do not need to spend time specifically to take out the steel wire, saving time and improving work efficiency.

3. Fully automatic with low labour cost

PLC control system is adopted in the continuous waste tire pyrolysis plant, which has a high degree of automation It requires only one person to control the PLC console. Feeding and slag discharge can be realized in a fully automatic manner. No manual work is required, which saves time and effort for customers, saves costs and improves profits. It is especially suitable in some areas with high labor costs.

4. Unique sealing design of both feeding and slagging system

Both feeding and slagging system of continuous waste tire pyrolysis plant adopts unique sealing design, which can effectively prevent pyrolysis oil gas from leaking through the feed inlet and slag discharge port, ensuring production safety and environment protection.

Unique sealing design of feeding

Unique sealing design of feeding

5. Large capacity with small land occupy size

The continuous waste tire pyrolysis plant has a large amount of processing capacity. It can handle 50T waste tires in one day, and it takes up very little space, saving customers space costs and increasing profits.

6. Continuous feeding and slagging save time and energy

Continuous waste tire pyrolysis plant can achieve 24 hours of continuous daily production, continuous feed and continuous discharge of slag, without interruption in the middle. It also improves the utilization rate of equipment.

Full set continuous waste tire pyrolysis plant

Full set continuous waste tire pyrolysis plant

To sum up, there are common points and differences between batch tire pyrolysis plant and continuous waste tire pyrolysis plant. You can choose according to your raw material handling capacity or budget.

We Doing company provide both batch and continuous waste tire pyrolysis plant with series models for you to choose. They all have passed CE, ISO, SGS certificates. Tell us your requirment, and our project manager will give you the most professional suggestions and solutions.