Waste Tyre to Fuel Oil Recycling Plant

Date:2018-05-31 15:40:27 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

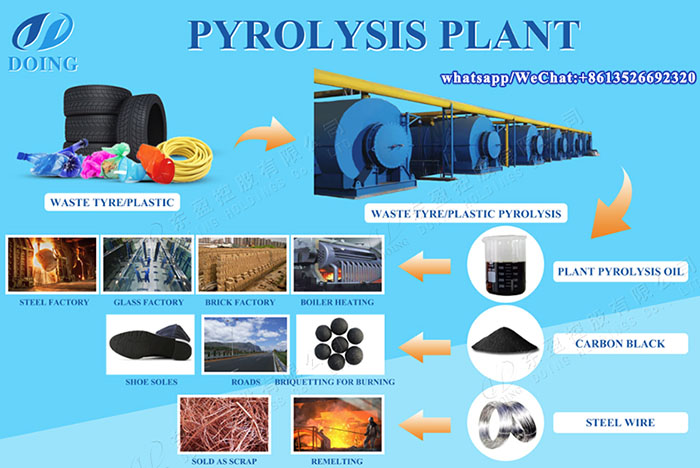

Waste tyre to fuel oil recycling plant can turn waste tyres into fuel oil, carbon black and steel wire. The manufacture of waste tyre to fuel oil recycling plant makes it a reality that waste tyres can be recycled into usable energy. This article will describe the waste tyre to fuel oil recycling plant in detail.

Waste tyre to fuel oil recycling plant installed in China

Waste tyre to fuel oil recycling plant installed in China

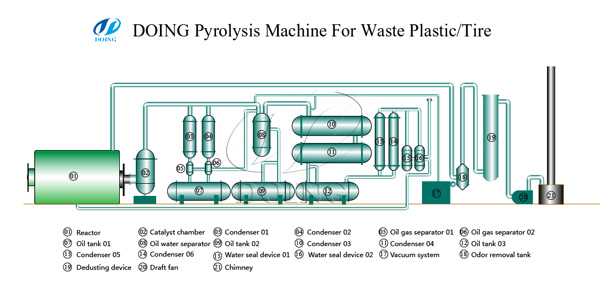

The main workflow of waste tyre to fuel oil recycling plant

1. Put the waste tyres into the reactor and rotate the reactor clockwise. Seal the inlet door to ensure no gas leakage.

2. Heat the reactor slowly with heating materials. When the temperature reaches about 250 degrees, the waste tyre will be pyrolyzed and produce oil gas.

3. Oil gas from the reactor enters the condensing system, which is cooled down to liquid oil. Thencollect liquid oil by the storage tank. Gases that cannot be liquefied under normal pressure will be recovered to the combustion system through a safety device. The gas can be used as fuel to heat the reactor.

4. After the liquid oil is collected, the reactor temperature will decrease. When the temperature drops to about 40 degrees, we can expel carbon black and steel wire.

The main workflow of waste tyre to fuel oil recycling plant

The main workflow of waste tyre to fuel oil recycling plant

Advantages of waste tyre to fuel oil recycling plant

As the leading professional pyrolysis plant manufacturer in China, the waste tyres to fuel oil recycling plant produced by DOING company have the following advantages.

1. Safety

Waste tyre to fuel oil recycling plant with mature safety devices, such as thermometers, pressure gauges, safety valves, electronic control systems. These safety devices can monitor the operation of waste tyre to fuel oil recycling plant at any time, and can ensure the accuracy and safety of operation.

2. Energy saving

Combustible gas that cannot be liquefied under normal pressure can be recycled and used as fuel to heat the reactor. The reuse of this gas can save fuel costs in the production process of waste tyre to fuel oil recycling plant.

3. Environmental protection

All parts of waste tyre to fuel oil recycling plant sealed well, will not leak. The flue gas produced in the production process is also treated by the smoke cleaning system to ensure that the exhaust smoke is pollution-free.

4. High efficiency

The waste tyre to fuel oil recycling plant can deal with the waste tyre in batch, so that the waste tyre can be converted into fuel oil thoroughly and efficiently.

The fuel oil obtained from waste tyre to fuel oil recycling plant

The fuel oil obtained from waste tyre to fuel oil recycling plant

Application of final product from waste tyre to fuel oil recycling plant:

The final products from waste tyre to fuel oil recycling plant are pyrolysis oil, steel wire and carbon black.

1. Pyrolysis oil can be used as industrial fuel material for combustion, or further refined into diesel oil by pyrolysis oil distillation plant.

2. Carbon black can be used as clay to make bricks or as industrial additive.

3. Steel wire can be sold directly or recycled to produce new steel products.

Application of final product

Application of final product

At present, waste tyre to fuel oil recycling plant is the most popular solid waste treatment method. DOING's waste tyre to fuel oil recycling plant are exported to more than 90+ countries and regions. If you plan to develop related waste to fuel recycling pyrolysis plant, please feel free to contact us for more machine information or have a factory tour.