Waste Tyre Pyrolysis Plant

Date:2018-04-23 19:45:42 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Waste tyre pyrolysis plant manufactured by DOING company can effectively turn waste tyres into pyrolysis oil, carbon black, steel wire and combustible gas by the pyrolysis principle. Now, waste tyre pyrolysis plant not only is a solution to waste tyre pollution, but also a highly profitable waste tyre recycling business. Let's get to the details of the waste tyre pyrolysis plant.

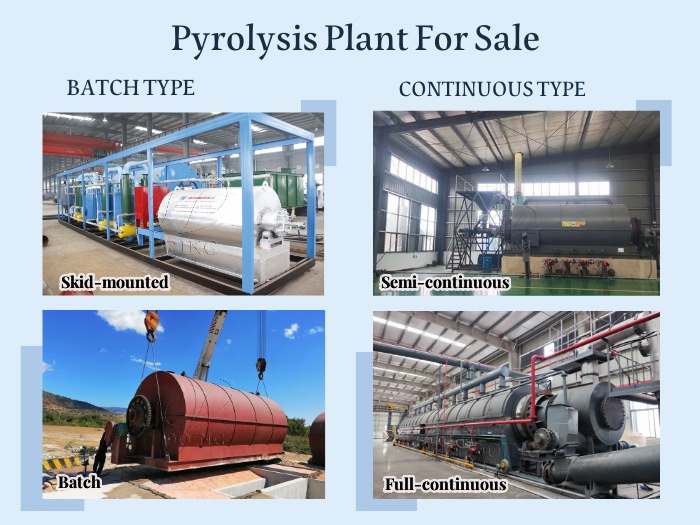

Waste tyre pyrolysis plant

Waste tyre pyrolysis plant

Main parts of waste tyre pyrolysis plant and their functions

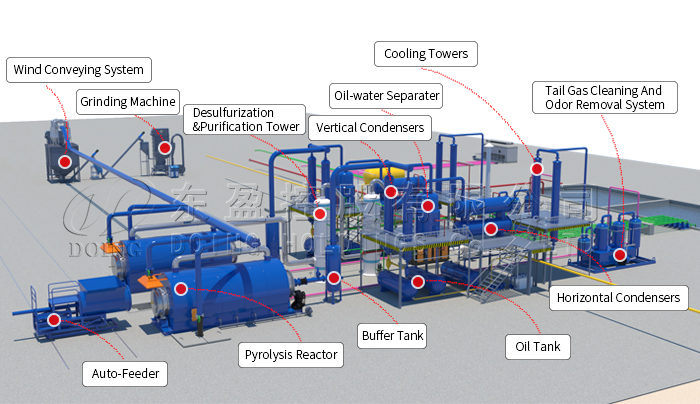

Main parts of waste tyre pyrolysis plant

Main parts of waste tyre pyrolysis plant

| NO. | Name | Functions |

| 1 | Auto-feeder | Used to feed the raw material into pyrolysis reactor. |

| 2 | Pyrolysis reactor | This is where the material is heated and pyrolyzed. |

| 3 | Buffer tank | Used to buffer the large amount of oil gas produced and ensure the smooth operation. |

| 4 | Oil tank | Used to store the obtained fuel oil. |

| 5 | Two vertical condensers | Used to cool oil gas. |

| 6 | Oil-water separator | Filter and clean the oil gas, prevent the backflow. |

| 7 | Two horizontal condensers | Used to cool oil gas. |

| 8 | Two cooling tower | Used to cool oil gas. |

| 9 | Tail gas cleaning and odor removal system | Used to clean and remove odor of tail gas. |

| 10 | Desulfurization & purification tower | Used to purify the smoke. |

| 11 | Wind conveying system | Used to collect carbon black. |

| 12 | Grinding machine | Used for further processing of carbon black, refined grinding powder. |

Specific working process of waste tyre pyrolysis plant:

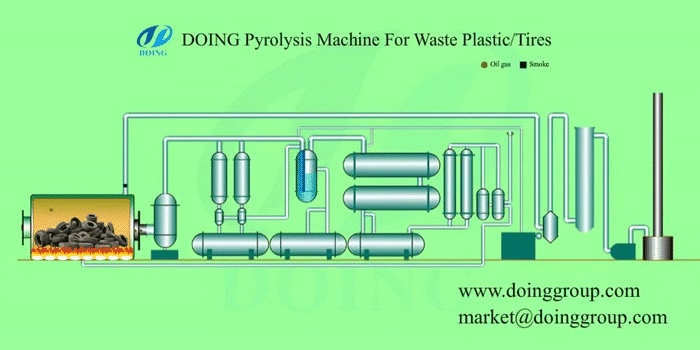

1. Feed the waste tyres into the reactor of waste tyre pyrolysis plant through a fully automatic feeder. The reactor should leave 1/3 of the space for smoother rotation. Then make sure the feeder door is closed.

2. The reactor is lightly heated by burning fuel (coal, wood, gas, or the last batch of produced tire oil). When the temperature reaches 100°C (250-280°C is the highest output rate interval), oil and gas will be released. The separated heavy oil gas from the manifold should be liquefied and dropped into a heavy tank. Lighter gas will rise to the oil condenser, liquefy into oil and store it in the tank. The non-condensable gas after dedusting by distillation and steam removal will be introduced into the recovery furnace.

3. After all fuel is generated, the reactor should be cooled. When the temperature drops 40 degrees, carbon black will be automatically discharged. If the raw material is the entire tyre, remove the wire from the reactor with a hook of at least than 50 degrees Celsius.

4. There may be a little exhaust gas, please discharge it after reaching the discharge standard.

5. Before starting the next batch, make sure all the work is done.

Working process of waste tyre pyrolysis plant

Working process of waste tyre pyrolysis plant

Once this tyre pyrolysis process is completed, the obtained final product includes steel wire, carbon black and tyre pyrolysis oil. This pyrolysis oil is commonly used in industrial fuel materials for combustion only and even for further refining the product into diesel fuel with DOING waste oil distillation machine.

Specific uses of final product of waste tyre pyrolysis plant are as follows:

1. Pyrolysis oil: Used in steel plants, boiler heating, heavy oil generators, cement plants,etc.

Uses of pyrolysis oil

Uses of pyrolysis oil

2. Carbon black: Used for pressure ball combustion, or refined milling, which can be used as a new tire, rubber soles, pigment manufacturing materials.

3. Steel wire: It is mainly used for recycling or remelting.

4. Combustible gas: It will be recycled by the waste tyre pyrolysis plant again, used for the heating material of the pyrolysis reactor, and it will save energy and reduce emissions.

It is because of these final products that the waste tyre pyrolysis plant project has a high profit.

Profit analysis of 12T/D waste tyre pyrolysis plant

Profit analysis(Reference to process 12T/D waste tyre pyrolysis plant) | |

Running cost / Day | |

Waste tyres | 12T*73USD/T=876USD |

Heating fuel (Just choose one from the options) | 1)Coal: 0.4T¥*58USD/T=23USD 2)Fuel oil: 0.4T*364USD/T=146USD 3)Diesel:0.3T*582USD/T=175USD 4)Natural gas: 150M3*0.33USD/M3=4.9USD |

Power consumption | 15Kw/h |

Water consumption | Water is for circulating use, no consumption |

Required workers | 3 workers per shift * 22USD =65USD |

Income / Day | |

Fuel oil | 4.5T*364USD/T=1637USD |

Carbon black | 1)selling directly,3T*73USD/T=218USD 2)grinding,3T*291USD/T=873USD |

Steel wire | 1.5T*116USD/T=175USD |

Daily profit (Use fuel oil for heating and sell carbon black directly) | 1302USD/Day |

DoingGroup's waste tyre pyrolysis plant has the following advantages:

Safety

1. Automatic welding, improve work efficiency, ensure quality of waste tyre pyrolysis plant, avoid accidents.

2. Special design to avoid paper jam caused by X-ray inspection and ensure safe operation.

3. The vacuum system ensures that the entire production line runs well.

Environmental protection

1. Dust removal and sulfur removal system to remove smoke and sulfur.

2. Exhaust gas (including methane to butane) will be directly recycled to the fuel furnace without gas pollution.

High oil yield

1. Three cooling processes ensure that the oil and gas are fully liquefied.

2. The catalyst chamber ensures complete pyrolysis of the feedstock.

Long lasting

1. Special boiler plate: Q245R with a thickness of 16mm.

2. Automatic welding ensures the service life of the waste tyre pyrolysis plant and the service life will reach 8-10 years.

Energy saving

1. The heating system of waste tyre to fuel oil pyrolysis plant is well-sealed, airtight, and fuel-efficient.

2. Exhaust gas will be recycled for reactor heating.

Good after-sales service

1. Overseas tour guides install and train customer staff and try to run.

2. One year warranty.

Project case

By now we have installed hundreds of waste tyre pyrolysis plant in more than 70 countries and regions:

Africa: Nigeria, Congo, Egypt, Uganda, etc;

Europe: Romania, Poland, Italy, Macedonia, Albania, Turkey, etc;

Asia: Malaysia, Pakistan, India, Thailand, Iran, Bangladesh, Lebanon, Jordan, etc;

America: Mexico, Ecuador, Haiti, Guatamala, Aruba, Panama, Jamaica, etc.

Oceania: Australia.

Below is the picture of the installation in some countries.

Waste tyre pyrolysis plant installed in some countries

Waste tyre pyrolysis plant installed in some countries

As a waste tyre pyrolysis plant manufacturer with 10 years of rich experience, Henan DOING not only can provide high quality waste tyre pyrolysis plant, but also can configure waste tyre pyrolysis plant according to your specific situation to help you arrange the project schedule.Contact us now for a free quote on waste tyre pyrolysis plant.