Waste tyres pyrolysis plant recycling oil

Date:2018-03-26 10:23:49 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Waste tyres pyrolysis plant also called waste tire pyrolysis plant, waste tyre derived fuel production plant. The waste tires pyrolysis plant recycling oil recovers waste tires into fuel oil, carbon black, waste steel wire, and flammable gas through the use of high-temperature pyrolysis process. And it can also recycle other organic solid wastes such as waste rubber, waste plastics, oil sludge, etc.

DOING waste tires pyrolysis plant recycling oil for sale

DOING waste tires pyrolysis plant recycling oil for sale

Project Background / Introduction

One of the raw materials for tire manufacturing is oil, which means waste tires can also be used to recycle fuel oil with the waste tires pyrolysis plants. Once tires are discarded or have other problems, they cannot be sent to the repair shop for second use, which may cause serious traffic accidents. So for the large number of waste tires produced each year, how to effectively recover and recycle renewable energy from waste tires to replace traditional energy and avoid pollution has become the main background and point of departure of Doing Group's research and development of waste tires pyrolysis plant.

Common recycling methods for waste tires

Common recycling methods for waste tires

Raw materials suitable for waste tires pyrolysis plant recycling oil

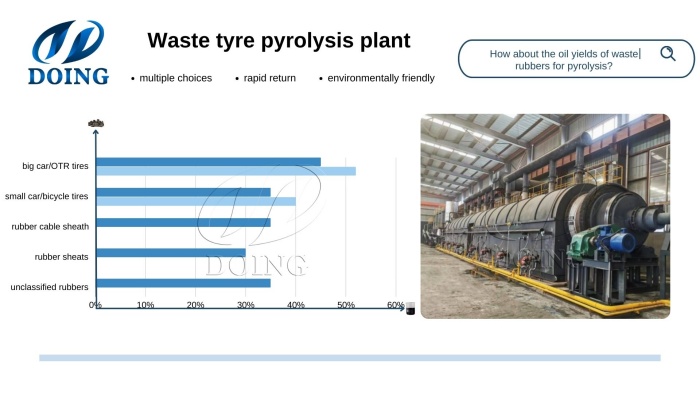

For waste tires pyrolysis plant, it can recycle various tires and rubber, including various machine tires(car/truck/bicycle/OTR tires), tire bead, inner tube, motorcycle tires, rubber cable sheath, rubber soles, all kinds of rubber sheets, and unclassified rubbers, which all have various oil yield based on their types and purity.

Oil yields of common waste tires

Oil yields of common waste tires

Main features of waste tires pyrolysis plant recycling oil

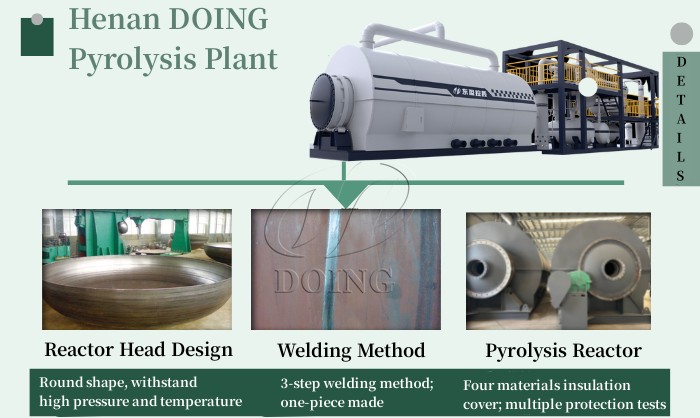

1. The reactor adopts 16/18/20mm Q245R or Q345R standard boiler plate and 304/314 stainless steel, which have good high temperature and high pressure resistance characteristics and can enhance long service life of reactor and work safety.

2. The outside of the reactor is equipped with an external thermal insulation system, made of four materials, ensuring that the temperature is not easily lost and improves the operating efficiency of the equipment.

Design details of DOING pyrolysis plant reactor

Design details of DOING pyrolysis plant reactor

3. The welding process for the reactor adopts the very unique three-step welding process. This welding technology can guarantee the tightness and compactness of the interface, enhance long service life and avoid cracking.

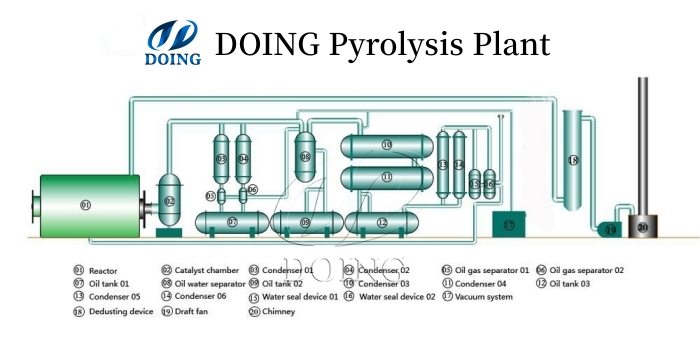

4. To ensure sufficient cooling of oil and gas and increase the oil yield, our waste tires pyrolysis plant adopts the most advanced and efficient three step cooling system and the water tank cooling system, which can meet different demands of our customers;

5. There are complete safety devices for our waste tires pyrolysis plant, including oil-water separator, water seal and vacuum device(DOING patented device), which can fully purify oil and gas, tail gas, and prevent backflow of oil and gas exhaust to enhance work safety to avoid flash explosion;

Vacuum device of DOING pyrolysis plant

Vacuum device of DOING pyrolysis plant

6. The waste tires pyrolysis plant has the dust removal and deodorization device, tail gas cleaning system, desulfurization tower and other environmental protection systems, which can completely meet the environmental protection department's assessment criteria for the three wastes generated, helping you quickly pass complicated approval procedures of the environmental protection department.

Work process of waste tires pyrolysis plant recycling oil

Put the waste tire into the reactor of the waste tire pyrolysis plant, and heat it. Then the waste tire will be cracked to generate oil gases. Then the oil gases are cooled into oil through the multi-stage cooling system. When the oil gases are all recovered, we are done with the work of recycling waste tires into pyrolysis fuel oil.

Work process of DOING pyrolysis plant

Work process of DOING pyrolysis plant

Obtained final products and wide applications

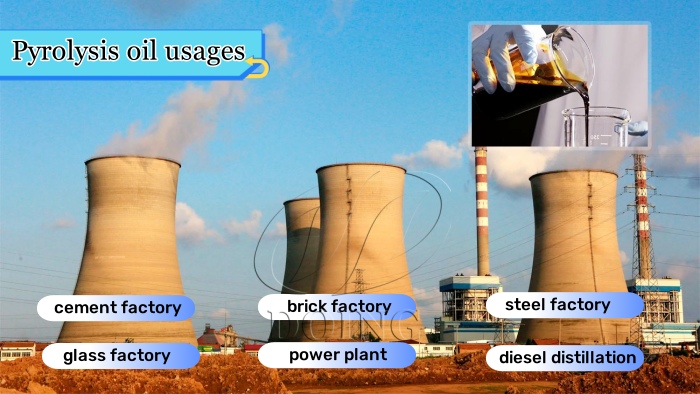

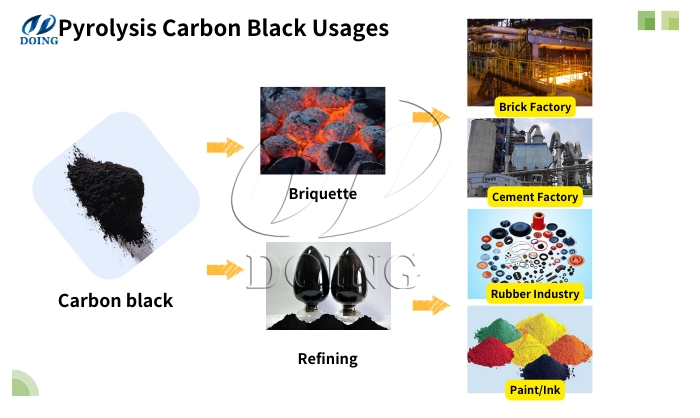

The main products of waste tires pyrolysis plant are 40-45% fuel oil, 30% carbon black, 15% waste steel wire, and 10% combustible gas. Tire oil is also known as fuel oil and can be sold directly (can also be used for processing or burning in boilers, bath centers, burning fuels such as floor tiles, cement factory, steel factory, glass factory, heavy oil generators, etc.) or deep processed into non-standard diesel with the waste oil distillation machine; carbon black can be used directly as fuel, or make further refinement to be used as paints or inks. The steel wire can be directly sold as a waste product to a waste factory, or it can be sent to a steel plant and recast.

Applications of obtained fuel oil

Applications of obtained fuel oil

Applications of obtained carbon black

Applications of obtained carbon black

Cooperation and development of waste tires pyrolysis plant projects

Over the past 14 years, DOING has been committed to researching and developing the advanced technology of waste tires pyrolysis plant. At the same time, we are also actively expanding overseas markets and have our warehouses and offices in Nigeria. According to the statistics of our company, our waste tires pyrolysis plants recycling oil have been exported to over 90 countries and regions, such as Mexico, India, Thailand, Kazakhstan, Italy, South Africa, Colombia, Nigeria, Russia, Brazil, the United States, Australia, Japan, Vietnam, etc.

Projects of DOING pyrolysis plants

Projects of DOING pyrolysis plants

All in all, waste tires pyrolysis plant recycling oil will be a project full of prospect and prosperity. If you are interested in our equipment, welcome to contact us directly!