How does a waste tire pyrolysis plant work?

Date:2018-03-21 09:54:01 Pyrolysis machine FAQ /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Waste tire pyrolysis plant

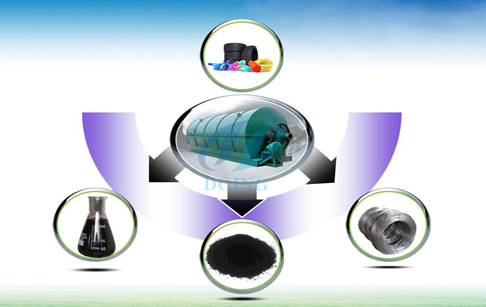

DoingGroup has developed a waste tire pyrolysis plant. This pyrolysis plant can complete the process that cracks waste tires into fuel oil, carbon black, and steel wire using the principle of pyrolysis chemistry.

Does tire pyrolysis plant working process difficult? It’s simple!!!

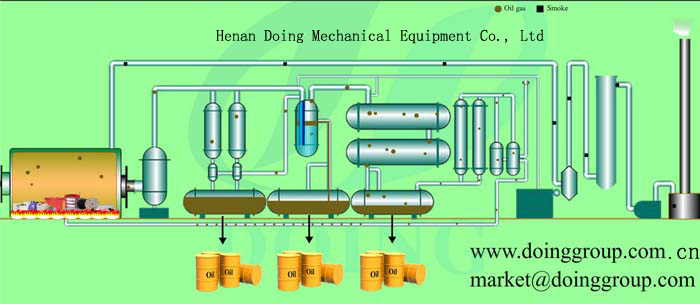

Waste tire pyrolysis plant working process

1. There are two options for feeding collected waste tires into the reactor:

(1) Feed the collected waste tires directly into the reactor via a pusher;

(2) The steel wire in the waste tire is first drawn out with a wire drawing machine, and then the waste tire is sent to the reaction kettle through the pusher device. It can reduce the damage of the wire to the reactor.

2. The reactor is heated with fuel. When the temperature reaches a certain height, the waste tire begins to crack into oil and gas.

3. The cracked oil and gas enters the condensing system and is liquefied into heavy oil and falls into the tank. The liquefied material will be recovered by the equipment and reused in the heating of the reactor.

4. Dust removal and deodorization of the heavy oil in the tank will result in fuel oil.

5. When the temperature of the reactor drops below 40 degrees, remove the carbon black (steel wire) from the reactor.

Waste tire pyrolysis plant

The yield of various materials used for the operation of DoingGroup's waste tire pyrolysis plant is 45-50% for fuel, 30% for carbon black, 15% for steel wire, and 10% for non-condensable gases.