Waste Plastic Pyrolysis Plant

Date:2018-03-14 14:29:03 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Waste plastic pyrolysis plant uses pyrolysis technolygy to pyrolysis waste plastic into pyrolysis oil, carbon black and uncondensable gas. Therefore,using waste plastic pyrolysis plant to dispose of waste plastic can not only protect the environment, but also these end products bring great profits to customers.

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

Application of end products of waste plastic pyrolysis plant.

1. Pyrolysis oil

Pyrolysis oil is a good heating fuel, which can be used in many industries, such cement factory, steel factory, heavy oil generator,etc. Besides, pyrolysis oil can be refined into diesel by waste oil distillation machine to get higher bussiness values.

2. Carbon black.

Carbon black can be used for industrial heating by made into pellets, its combustion calorific value is equivalent to that of coal, and it can be used directly instead of coal. Carbon black can be also further refined into 325 mesh or 800 mesh to make new tires, shoe soles, painting materials, etc.

3. Uncondensable gas.

The uncondensable but combustable gas will be produced in the pyrolysis reaction. The uncondensable gas can be collected by Industrial pressure vessel to heat the pyrolysis reactor or for further heating use.

Application of end prodects

Application of end prodects

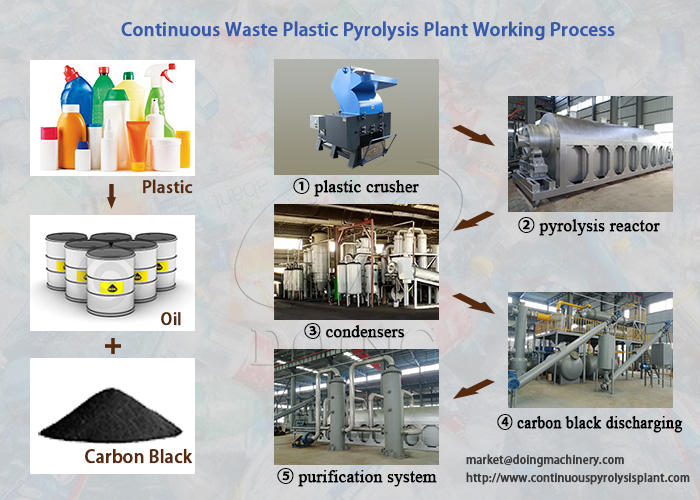

Working process of waste plastic pyrolysis plant.

1. Use the feeding machine to send the waste plastic into the pyrolysis reactor, and then heat the pyrolysis reactor with fuel;

2. When the temperature of the pyrolysis reactor reaches a certain temperature, oil gas will be produced, and the oil gas will be cooled down into pyrolysis oil through the cooling system.

Uncondensable but combustable gas can be recycled by industrial pressure vessel to heat pyrolysis reactor;

3. After the pyrolysis reaction is over, wait for the temperature of the pyrolysis reactor to drop below 40 degrees, and then open the carbon black discharge port of the pyrolysis reactor to discharge carbon black.

4. Collect the carbon black with the carbon black discharge device.

Working process of waste plastic pyrolysis plant

Working process of waste plastic pyrolysis plant

Environmental protection measures of waste plastic pyrolysis plant.

As we all know, waste plastics are relatively polluting to the environment. If the waste plastics are handled in an inappropriate way, it will cause greater pollution to the environment. Therefore, Doing Group has specially developed the environmentally friendly waste plastic pyrolysis plant.

The environmental protection system of waste plastic pyrolysis plant includes tail gas cleaning system and smoke cleaning system. The bad smelland harmful tail gas (that is, uncondensable gas) generated during the pyrolysis reaction is purified by the tail gas cleaning system and collected by the industrial pressure vessel to heat the pyrolysis reactor. This not only prevents the tail gas from causing harm to the environment and the human body, but also makes full use of resources. The smoke generated during the fuel combustion process can be discharged after being processed by the smoke cleaning system, and will not cause secondary pollution to the environment.

The waste tire pyrolysis plant produced by Doing Group has passed the European and American environmental standards and we have installed equipment in more than 80 counties around the world.

Environmental protection of waste plastic pyrolysis plant

Environmental protection of waste plastic pyrolysis plant

Doing Group has dedicated to the waste plastic pyrolysis plant for more than 10 years, having our own production factory and professional installation team. If you want to know more information about waste plastic pyrolysis plant, welcome to contact us feel free.