How does cooking oil refining machine work?

Date:2017-07-13 10:37:43 Cooking oil machine FAQ /Give me the price / Leave a message- Tel: 0086-371-5677 1823

- Whatsapp/Cel: 0086 135 2662 7860

- Email: market@doinggroup.com

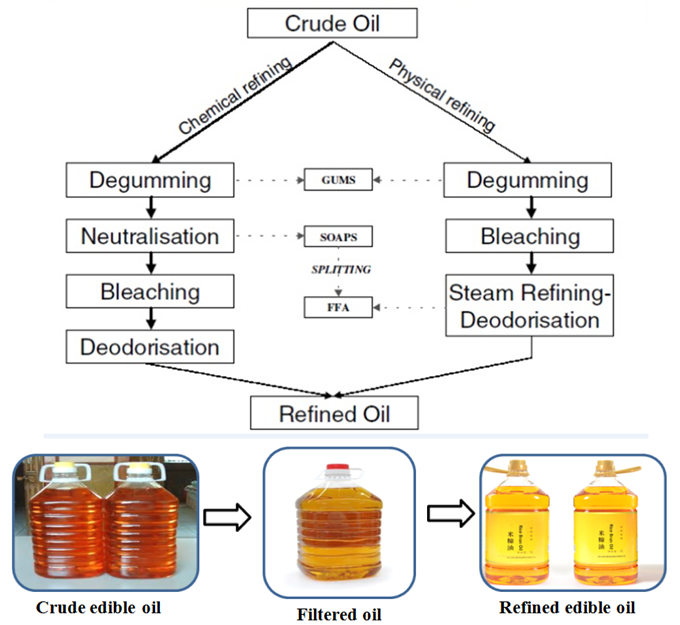

The edible oil refinery can refine almost all types of oils. The refined oil can meet the quality specification. For refining the edible oil, there are four basic processes in the cooking oil refining,they are Degumming Process, Deacidification Process, Decolorization(Bleaching) Process, Deodorization Process.

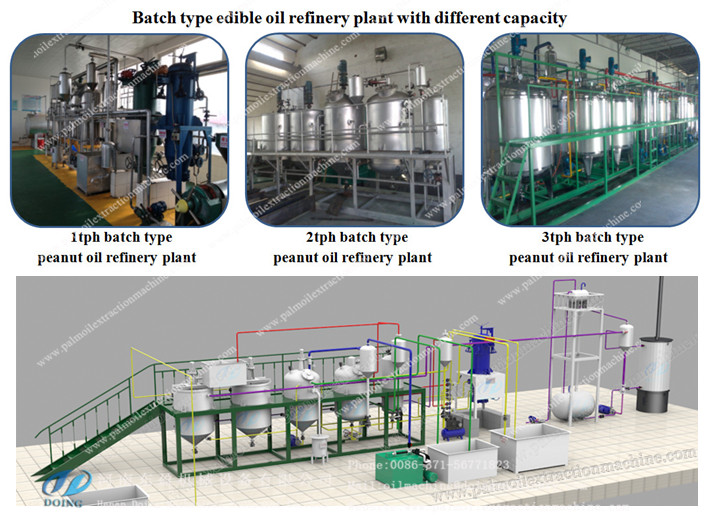

Cooking oil refining machine

Main small scale cooking oil refining steps :

1. Degumming: Removing the phosphatide by adding hot water, when phosphatide meets hot water, it will become bigger and bigger, then out of tanks.

2. Deacidification: Removing the FFA by add alkali liquor (for taking neutralization reaction).

3. Decolorization(Bleaching): Remove the pigment by adding bleaching earth( it has strong adsorption of pigment), and the remaining bleaching earth will be filtrated by leaf filter.

4. Deodorization: Remove the oxide, solid particle and volatile gas.

Cooking oil refining process

Technological process of small scale cooking oil refining machine:

1. It's a kind of intermittent small senior edible oilrefining equipment .

2. This is the special equipment for degumming,deacidification,decoloration,deodorization(senior edible oil,salad oil).

3.The complete set of small scale cooking oil refining machine includes heat conduction oil furnace,steam generator.It can process chemical refining without purchasing other pots.

4.Because deodorized tea seed oil,rice bran oil and corn germ oil etc. are with much fat or wax,they should be further dewaxing and degrease.

Working Process Description of cooking oil refining machine:

For refining the edible oil, there are three basic processes in the refinery. First process is neutralizing the oil in the neutralizer to remove the Free Fatty Acids (FFA) by adding caustic soda. Oil is heated up to about 60°C by thermic fluid coils and oil is stirred by stirrer. Then soap stock formed due to chemical reaction is allowed to settle at the bottom of the neutralizer from where it is taken out into soap pan.

Neutralized oil is drawn into the second vessel called bleacher where color of oil is removed by bleaching process with aid of chemicals such as carbon black and bleaching earth. Oil is generally heated up to 110°C by thermic fluid coils. Stirring is also continued. Bleaching process is done under vacuum.

Bleached oil then goes to the filter press where bleaching earth and chemicals are separated and clean bleached oil is then drawn to deodorizer where oil is heated above 110°C through thermic fluid coils and then live steam is given to the oil from the bottom steam nozzles and temperature of oil is raised up to 200 to 220°C through thermic fluid coils. Entire process is done under high vacuum. Thus smell is removed from the oil in the deodorizer. Then it goes to cooler where water circulating coils take away heat and oil is cooled. Again it goes to second filter press where completely refined and transparent color less oil is obtained.

Thermic Fluid Boiler, Vacuum Pump, Barometric Condenser, Catchalls, Steam Generator etc. play their role in the refining process. So these equipments are part of the refinery and connected with the vessels through pipelines.

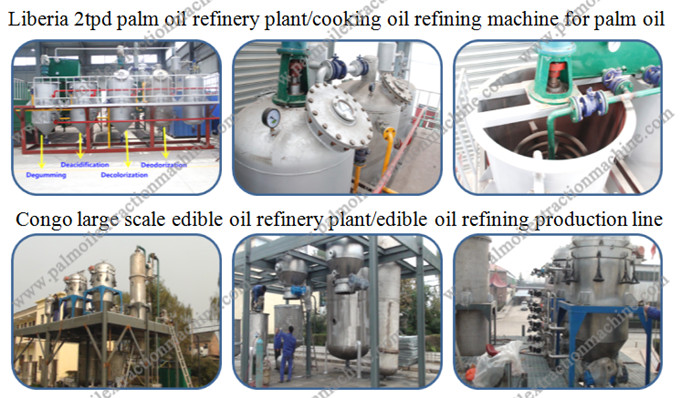

Cooking oil refining projects in different countries

Main features of small scale cooking oil refining machine:

1.This equipment is easy operation.

2.It needs small area.

3.The oil product is good-quality.

4.It is suitable for intermittent animal and vegetable oil refining.

5.The oil needed to be refined per day is below 30 tons.

Application area:

Plant oil,such as palm oil,soybean oil,rice bran oil etc,animal oil,oil materials with high acid value and more impurities.