Extrusion pretreatment of cooking oil

Date:2016-11-08 17:54:53 Cooking oil machine FAQ /Give me the price / Leave a message- Tel: 0086-371-5677 1823

- Whatsapp/Cel: 0086 135 2662 7860

- Email: market@doinggroup.com

Extrusion pretreatment of oil, fuel oil prior to solvent extraction were pretreated Extrusion is a new process. Extruded, also known as organized or structured materials for heat treatment in a specialized extrusion machine, after kneading, squeezing, gluing, vacuum dried puffed and subsequent cooling, making it have some kind of structured product.

Cooking oil extraction machine

Cooking oil extraction machine

And the effect of changes in oil extrusion pretreatment occurred

1. born after embryo strong role heating and extrusion, rapid and thorough destruction of oilseeds cells, the fat droplets evenly spread and cohesion, is conducive to oil extraction.

2. raw embryo gelling starch pasting, protein structured to form a porous granular and strong "mature embryo", when solvent extraction to improve the permeability and leaching rates.

Oil extrusion pretreatment

Oil extrusion pretreatment

3. The bulk density of the extruded pellets compared with embryogenic significantly improved, thereby improving the handling capacity of the leaching equipment.

4. extrusion can be active or passive oil of certain enzymes, beneficial to oil storage. Since lipolytic enzymes, fresh rice bran is difficult storage and 30 days storage in the summer, i.e., an acid value of 4.5 by the original acid value rose to 100. And by the extrusion of rice bran 130 ℃, the water dropped from 13% to 8%, 60 days storage, the acid value rose only to 8.0.

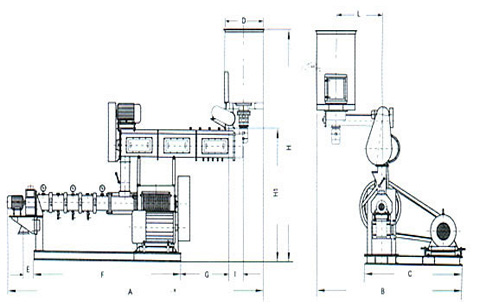

Extrusion device structure

Extrusion device structure

In the cylindrical bore of the machine with a screw extruder, which is having a varying pitch or a change in the original thread root diameter of the screw shaft. Protruding broken blade on the machine bore wall, a piece of material at the outlet of the die hole having a certain shape of the template. Place the template with the shaft has an outer cutter. Near the feed end of the outer wall of the casing fill line valve for regulating water into the swelling material. Near the discharge end of the outer wall of the housing there are several direct steam valve is used as a heating source, in order to avoid the heat generated from the friction alone reach the expansion temperature, and can reduce the power consumption of the device