Pyrolysis of plastic waste to oil ?

Date:2013-06-25 18:58:38 Pyrolysis machine FAQ /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Pyrolysis of plastic waste

What is pyrolysis:

Pyro = heat. Lysis = break down.

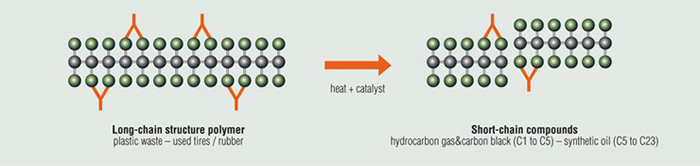

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Pyrolysis of plastic waste to oil machine

Plastic pyrolysis is: the process of converting waste plastic into industrial fuels like Pyrolysis Oil, Carbon Black and Hydrocarbon Gas.

Plastic pyrolysis involves subjecting plastic to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis plastic breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. Pyrolysis is great a way of recycling waste plastics. This plant can also used for waste tire recycling.

Raw material Oil ratio

PP (microwave oven food box/yogurt bottles etc) 50%-75%

PE(plastic film /plastic wrap) 50%-75%

PS (smack-box/blister box) 50%-75%

ABS (engineering plastics) 40%

Leftovers of paper Wet 15-20%, dry 60%

House garbage 35-50%

Plastic cable 80%

Plastic bag 50%

PVC (raincoat/building materials) Not suitable

PET (water bottles/sodas beverage) Not suitable