Continuous tyre process pyrolysis plant

Date:2013-06-25 17:51:40 Continuous Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Continuous waste tyre process pyrolysis plant

According to different customers and raw materials, Doing group supply different models of batch and continuous pyrolysis plant. Here we are going to introduce the continuous pyrolysis plant. There are several types of continuous pyrolysis plant according to the difference of materials mainly including the continuous plastic pyrolysis plant and the continuous waste tyre pyrolysis plant.

Through continuous improvement and constant technology upgrading, Doing have designed the Continuous tyre process pyrolysis plant which can convert tyre into useful resources more efficiently. This pyrolysis planti nclude DY-30, DY-50 and DY-50 and the daily processing capacities range from 30 to 50 tons.

The main feature of this Continuous tyre process pyrolysis plant is that they can work continuously for 24 hours per day without a stop .

Continuous tyre process pyrolysis plant pyrolysis process waste tyre to fuel oil and carbon black

But at first the Continuous tyre process pyrolysis plant is batch type, which has low automation and mainly operated by labour. This batch type pyrolysis plant needs to be stopped after every process for discharge residues (carbon black and steel wire) and feeding tires again. For one complete process, it takes about 16-20 hours, almost one whole day. And this batch type pyrolysis plant cannot process big quantity feedstock. For safety consideration, it only can process at most tons tyres per day. This is enough for the personal business. But for large scale waste tyre dealing companies or government projects, this kind of batch type Continuous tyre process pyrolysis plant may not meet their demand. So, as the increasing demand of the market and imprving technology, last year we just developed a new design as Manufacturers Continuous tyre process pyrolysis plant .

Fuel Oil (45% to 52%)

Fuel oil application

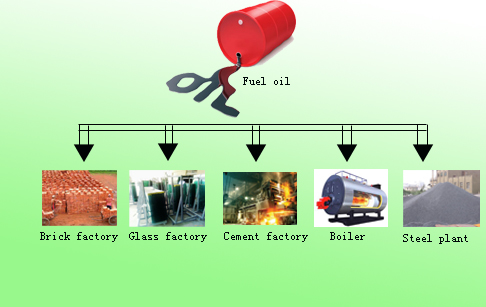

The main application of oil products produced by our manufacturers Continuous tyre process pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Carbon black application

Carbon black (30% )of Manufacturers Continuous tyre process pyrolysis plant carbon Black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% of the total amount of scrap plastics recycled in the system.Carbon black can application to electric cable jacketing,black nylon bag,rubber additive

Oil gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Steel Wire (12% to 15%)

The third product of Continuous tyre process pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.