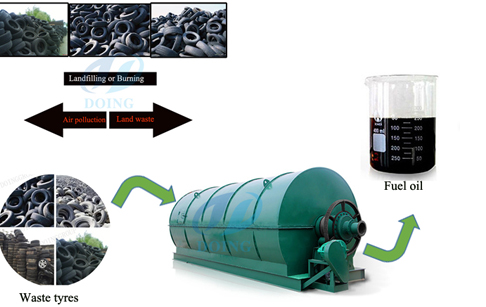

Rubber tyre recycling machine

Date:2016-02-19 11:14:16 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Doing rubber tyre recycling machine can convert waste rubber into high grade diesel fuel. Waste rubber are long chain polymers containing more than 50000 carbon atoms attached to each other in a cross linked or straight chain.During waste rubber pyrolysis, this long chain is broken down into smaller chain. The waste rubber recycing machine turns waste materials into gases and liquids. The end products can be used in any standard diesel engine or generator with little or no modifications.

In waste rubber to fuel oil, the polymer waste is not burned, instead it is broken down into usable finished products like Pyrolysis Oil, Hydrocarbon Gas and Charcoal.

Rubber tyre recycling machine

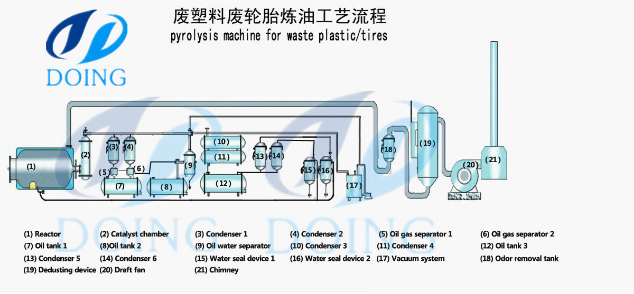

Rubber tyre recycling machine working process

Rubber tyre recycling machine woking process

1. Put waste rubber tyre into reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste tyre will be transferred to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the tyres/plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

After all these steps, you can start another batch.

Find product application of rubber tyre recycling machine

Find product application of rubber tyre recycling machine

1.Rubber tyre fuel oil: Oil from our rubber tyre recycling machine can be used as industrial fuel materials for burning.

2.Carbon black: Carbon black from this machine is crude, so you can sell it to the brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. You can take carbon black for deep processing .