How can old tires be converted to fuel oil?

Date:2013-06-25 16:13:50 Pyrolysis machine FAQ /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Waste tire pyrolysis plant

With auto industry growing strongly, 50%-55% raw rubber are used for tire manufacturing every year. Auto should change tires every 30,000-50,000 km, in this way, 17 million tons waste tires produced in one year.

Waste tyre/plastic/rubber is refractory and needs hundreds of years before not affecting plants growth in the world takes up quantities offarmland, breeding some diseases (dengue fever etc), destroys vegetation. If used for fuel or burned, no plants will grow in surrounding field. Thus to figure out an efficient and environmental way to dispose the waste tyres is such important for the green world.

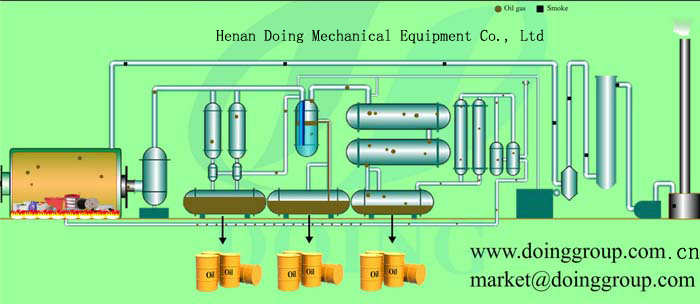

Waste tyre pyrolysis plant

The waste tyre pyrolysis plant is a machine that converts waste plastic,tires and rubber and other waste materials into pyrolysis oil, carbon black and hydrocarbon gas. The pyrolysis project can reduce the volumes of the waste products and help human protect the environment.

How can old tires be converted to fuel oil?

Converted waste tire to fuel oil working process

1. Feed raw material (waste tire、plastic) into reactor by full-automatic feeding machine. The reactor is supposed to be left 1/3 space for rotating more smoothly. Then make sure the door of feeding machine is closed.

2.Pyrolysis process: reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from last batch). The oil gas will be released when the temperature reached 100℃(250-280℃ is the top output rate interval). Heavy oil gas separated by manifold is supposed to be liquefied and drop down into the heavy oil tank. The lighter gas will rise up to the oil condensers, be liquefied in to oil and stored in the oil tank. The incondensable gas though dusulphurization and dedust by hydroseal will be led to the furnace for recycling.

3..After all fuel oil is produced, the reactor should be cool down. Carbon black will be discharged automatically when the temperature falls down 40 degree. If the raw material is the whole tire, please take out steel wire form the reactor by hooks below 50 Celsius at least.

4.There possibly will be a little exhaust gas left, please must expel it after reaching emission standard. 5. Before starting next batch, make sure all the work has been done