Waste plastic and tyre pyrolysis recycling plant

Date:2015-11-30 16:13:50 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Waste plastic and tyre pyrolysis recycling plant

Waste plastic and tyre pyrolysis recycling plant not only can process waste plastic/tyre/rubber ,but can convert waste plastic/tyre/rubber to fuel oil .

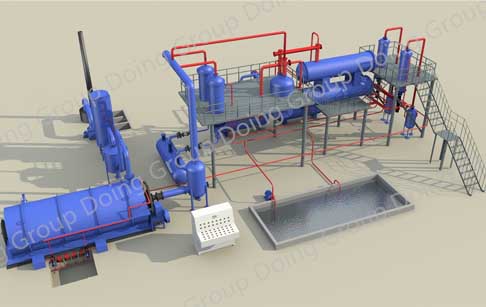

3D picture of waste plastic and tyre pyrolysis recycling plant

Plastic and tyre pyrolysis involves subjecting plastic and tyre to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis plastic and tire breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. Like plastic and tyre, pyrolysis end products are also hydrocarbons. Pyrolysis is great way of recycling waste plastics and tyres.

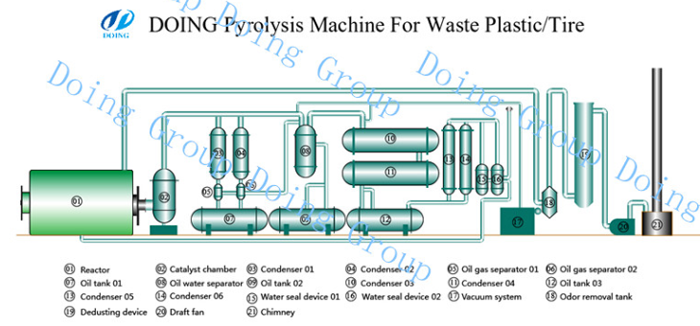

Waste plastic and tyre pyrolysis recycling plant working process

Waste plastic and tyre pyrolysis recycling plant working process

1. Put raw materials into reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste tyre will be transferred to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the tyres/plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

After all these steps, you can start another batch.

Waste plastic and tyre pyrolysis recycling plant main advantage

Waste plastic and tyre pyrolysis recycling plant

The Waste plastic and tyre pyrolysis recycling plant have no pollution to the environment,but also can bring much profit for us.

1.Gas. From our pyrolysis plant , there are 2 kinds of gas, one is gas from feeding material, like coal, wood etc, this gas will go through the dedusting system, gas after dedusting system is very clean, almost like steam. We have the SGS report for this part gas, it can reach international standards. Another part gas is uncondensible oil gas, this part gas we will recycle to furnace for heating reactor as energy. So gas no pollution.

2.Water. Like gas, water also have 2 parts. One part is for cooling down oil gas, this part water is pumped through the pipe, oil and water are always indirect contact. The water in the circulating system is always clean. Another part water is concluded in dedusting system, water film dust removal system use high-pressure hydraulic pump to press water into high pressure nozzle which atomize the water to clean the smoke from furnace, this part water is also circulating. So water no pollution.

3.Noise. The main noise from pyrolysis plant is draft fan, noise is <50db. So no noise pollution.

4.Smell. If you burn waste tire directly will cause bad smell and make pollution to the environment., but our plant is totally sealed, no bad smell come out. So no smell pollution.

Pyrolysis plant is no pollution and it can help you solve your countries’ waste tire pollution problems. Over than million tons of waste tires and plastic were disposed by our pyrolysis plant yearly.