Tyre pyrolysis plant for sale

Date:2013-06-20 21:57:14 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Tyre pyrolysis plant to be shipped abroad at Qingdao Port

Tyre pyrolysis plant to be shipped abroad at Qingdao Port

Tyre pyrolysis plant for sale

Type:DY-1-10

Processing Capacity:10T tires/24h

Reactor Size:D2600mm*L6600mm

The scene of tyre pyrolysis plant in Mexico

Tyre pyrolysis plant could be able to Automatic feeding, automatic slag, automatic alarm, automatic decompression, automatic adjustment of negative pressure, exhaust automatic recovery. Only need two workers to control the whole system, can save your cost.

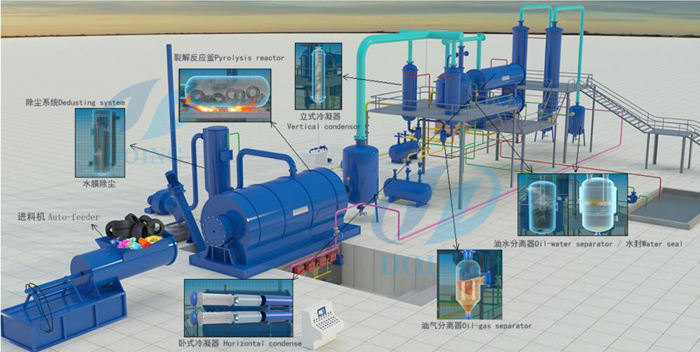

Tyre pyrolysis plant pyrolysis waste tyre to fuel oil Working process:

Tyre pyrolysis plant pyrolysis process waste tyre to fuel oil

1) feed the raw material into furnace automatically or manually, then seal the feed inlet system.

2) heat the reactor by burning the fuel material(coal,or wood,or natural gas ,oil ) in the combustion system.

the reactor will slowly become heat ,when the temperature reach around 250 degree Celsius, the oil gas will be formed.

3) After processed by our technology, the oil gas will go to cooling system for cold liquid oil.

the gas which can not become liquid under normal pressure , will be designed to go back to combustion system through safety device instead of the fuel material to burn the reactor, which is environmental friendly and can save you much energy.

4)After finished oil produce ,the temperature of reactor will be down,while,carbon black can be discharged automatically.

5) when the temperature fall down to 100 degree Celsius,worker could opened the door of reactor to discharge of steel wire.

6) Then can start to another batch working.

| Technical parameter of tyre pyrolysis plant | ||||

| NO. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | tires/Plastic | tires/Plastic | tires/Plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7ton | 3.6 ton | 4.5 ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Marerial of Ractor | Q245R | Q245R | Q245R |

| 8 | Thickness of Ractor | 14mm | 14mm | 14mm |

| 9 | Rotate speed of Ractor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 12KW | 12KW | 12KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condensor | 40㎡ | 40㎡ | 53㎡ |

| 14 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 16 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 17 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 18 | Working form | Intermittent opration | Intermittent opration | Intermittent opration |

| 19 | Delivery time | 20days | 20days | 20days |

| 20 | Weight | 27T | 30T | 35T |