PCB board recycling machine

Date:2015-11-25 18:08:22 Copper wire recycling machine /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

PCB board recycling machine brief introduction

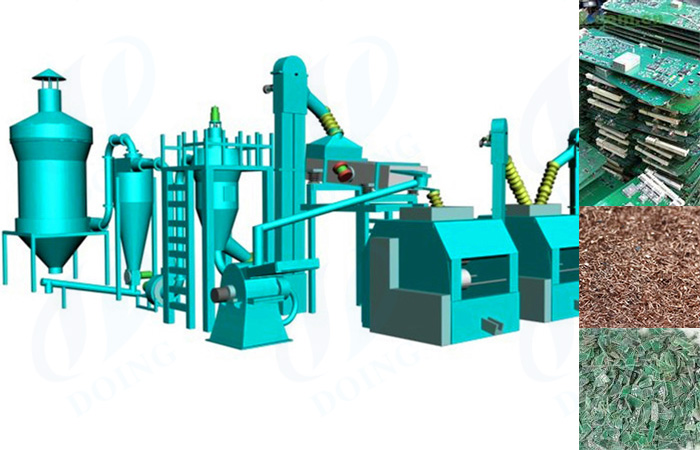

PCB board recycling machine

PCB board recycling machine is developed in cambination with advanced domestic and foreign technology .thePCB board recycling machine adopts advanced recycling process by physical methods ,such crushers and high voltage electrostatic separation devices developed by the company are of strong innovation,and their process lines for resource recycling are advanced and reasonable .

PCB board recycling machine feature

PCB board recycling machine

1.Little noise

2.No need for water

3.Without dust polluction

4.High metal recovery rate

5.Saving motive power and human power

6.Without Wastes.

7.98% metal and nonmetal can be fully separated.

PCB board recycling machine working process

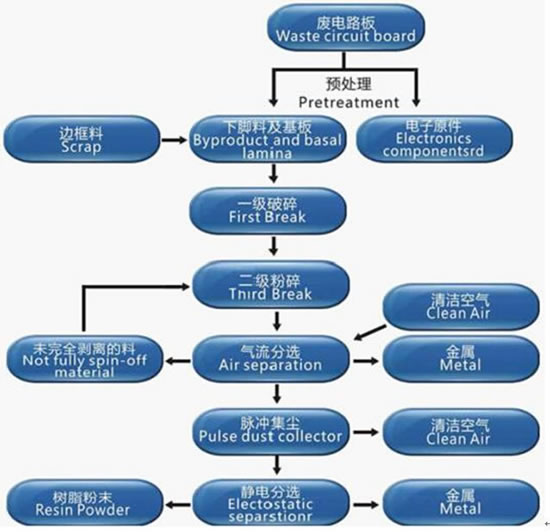

PCB board recycling machine working process

1.Generally, it goes first crusher, second crusher, air separator,high electrostatic separator,or gravity separator, you can also get different metals separately, such as: copper, tin, and other precious metals (gold, silver, etc.) from our mixing metals.

2.Because of the special physical characteristics of E-waste circuit boards, our equipment are adopt the dry-type grinding and separating technique to recycle and reuse.

3.The printed circuit boards will be separated into metal powder and resin fiber powder. First, the waste circuit boards will be crushed into small pieces, then will be grinded into the powder mixture of metal and resin fiber. The mixture will be completely separated via pulse air flow separation to get 97% mixed metal powder.

4.Finally, the rest mixture powder will go into the high voltage electrostatic separator, the purity can be up to 99.9%, and the impulse dust catcher is approached to efficiently prevent the dust pollution.

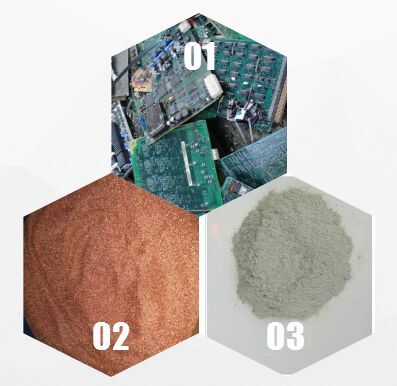

PCB board recycling machine final product

PCB board recycling machine final product