Scrap tire derived fuel pyrolysis plant

Date:2015-11-18 16:11:31 Pyrolysis Plant /Give me the price / Leave a message- Skype: bonniezhao2

- Tel: 0086-371-5677 1821

- Whatsapp/Cel: +8613526692320

- Email: market@doinggroup.com

Scrap tires

More than 250 million scrap tires are generated annually in the United States and their proper management continues to be a solid waste management concern. Sound markets for scrap tires are growing and are consuming an ever increasing percentage of annual generation, with market capacity reaching more than 75 % of annual generation in 1996. Of the three major markets - fuel, civil engineering applications, and ground rubber markets - the use of tires as a fuel is by far the largest market. The major fuel users include cement kilns, pulp and paper mills, electrical generation facilities, and some industrial facilities.

Scrap Tires are an ubiquitous by-product of contemporary social and economic society. Our personal mobility is almost entirely dependent on the pneumatic tire, whether in automobiles, buses or even airplanes. The transport and delivery of most goods is also dependent on the pneumatic tire. To recall an old slogan of the American Trucking Association, "If you got it, a truck brought it", and it goes without saying that the truck was riding on pneumatic tires.

Scrap tire derived fuel pyrolysis plant

The scrap tire derived fuel pyrolysis plant can effectively convert waste tire into fuels, like Oil, Carbon Black, and Hydrocarbon Gas etc. Here, the raw material is either waste tire or waste plastic. Then, the recycleables are heated from the reactor to be able to generate fuels, oil, and gas.

Scrap tire derived fuel pyrolysis plant advantage

3D picture of scrap tire derived fuel pyrolysis plant

1.Using Scrap tire derived fuel pyrolysis plant available for sale, stick to experience an excellent, eco-friendly & cost-effective solution for tyre recycling.

2.On an average, the entire pyrolysis process may lead to a yield of around 45-52% oil, 30-35% charcoal, and 15% gas. The oil produced is mainly made up of diesel, kerosene, benzene, fuel oil & heavy fuel oil. Hence, the produced oil may be further refined and useful for operating any vehicle.

3.The plant pollution has truly get to be the most problem nowadays. Obviously, scrap tire derived fuel pyrolysis plant give you a meaningful strategy to it while promoting an eco-friendly solution by reduction of the hazards of land pollution due to the waste tire.

4.By converting the waste into energy, Scrap tire derived fuel pyrolysis plant offers an alternative energy source too.

Scrap tire derived fuel pyrolysis plant falls beneath the following kinds of industrial projects

1.Waste to energy project

2.Renewable energy project

3.Waste tire and plastic control equipment

4.Petrochemical

5.A sustainable pollution control equipment

Scrap tire derived fuel pyrolysis plant final product application

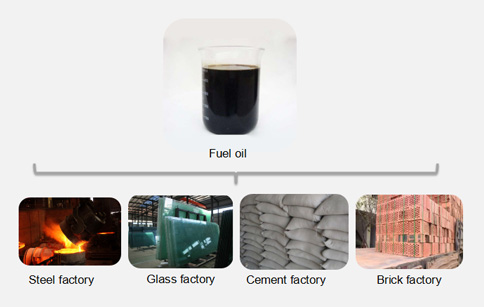

Fuel Oil

Fuel oil application

The fuel oil is between 45 and 52 percent. This fuel oil does apply in power plant factory, ceramic factory, aluminum factory, glass factory, painting factory, boiler system factory and boiler factory.

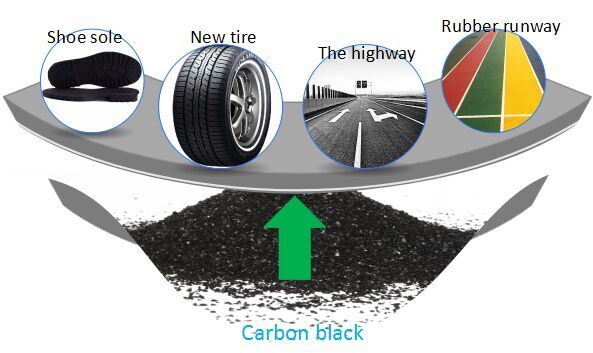

Carbon Black

Carbon black application

The proportion found as soon as the recycling is 30 to 35 percent of carbon black. This device works extremely well within the electric cable jacketing, doormat and hose mat, conveyor ban, rubber addictive, automatic spare parts, heat isolation plus more.